SK32 firebrick, a high-quality refractory material classified under the JIS (Japanese Industrial Standard) R-series, has been widely used in industrial furnaces, kilns, and high-temperature applications since the mid-20th century. Originally developed in Japan for steelmaking and ceramic production, SK32 became a benchmark for mid-range refractories due to its balanced alumina-silica composition, offering excellent thermal shock resistance and moderate refractoriness (around 1650°C). Over time, its production expanded globally, with China emerging as a leading manufacturer by leveraging cost efficiency and technological adaptation.

China’s Competitive Edge in SK32 Firebrick Production

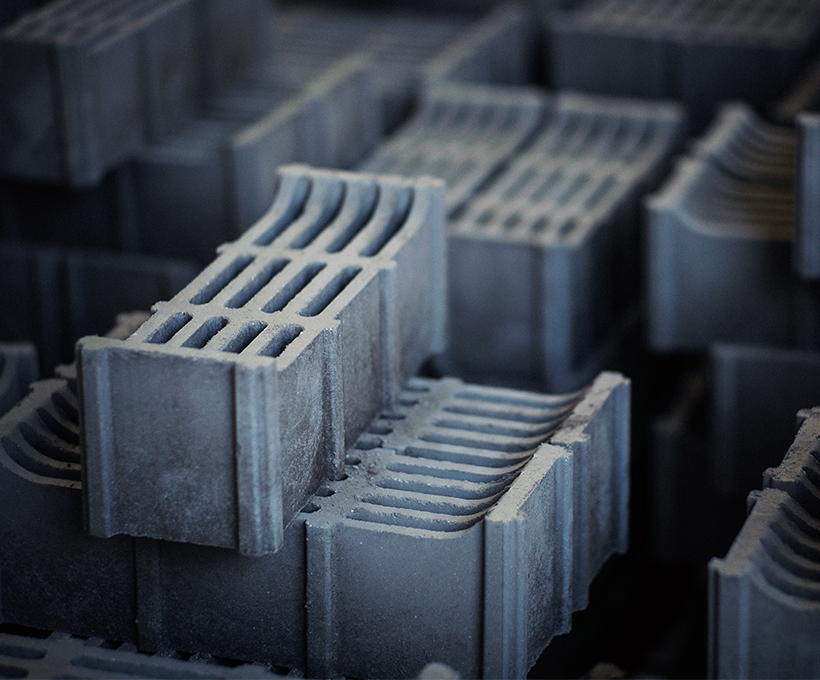

China dominates the SK32 firebrick market due to several key advantages. First, the country possesses vast reserves of high-purity raw materials, including bauxite and silica, essential for consistent quality. Advanced manufacturing techniques, such as precision pressing and high-temperature sintering, ensure uniform density and enhanced mechanical strength. Additionally, China’s vertically integrated supply chain—from raw material processing to finished product distribution—allows for competitive pricing without sacrificing performance.

Chinese manufacturers produce SK32 bricks with renowned durability, low porosity, and slag erosion resistance, making them ideal for blast furnaces, rotary kilns, and foundries. Many manufacturers also offer customized shapes and sizes to meet specific industrial needs, backed by rigorous ISO and ASTM compliance testing. This adaptability, combined with China’s ability to scale production rapidly, has solidified its position as the top global supplier.

Future Innovations and Sustainability

Looking ahead, Chinese producers are investing in eco-friendly SK32 variants, incorporating recycled materials and energy-efficient kiln technologies to reduce carbon footprints. Research into nano-bonded additives aims to further improve thermal conductivity and lifespan. By merging traditional craftsmanship with cutting-edge R&D, China continues to set the standard for SK32 firebrick performance, ensuring its relevance in next-generation industrial applications.

- Preheating Insulation Material9 个产品

- Aluminum processing industry35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Bricks15 个产品

- Cement industry35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Environmental and energy solutions35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Industry Ceramic Material1 个产品

- Non-ferrous metal smelting industry35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Refractory Raw Material11 个产品