Rotary Kiln

(I) Types and Structure of Rotary Kilns

The rotary kiln is the primary thermal equipment in the cement industry. Depending on production characteristics, it can be classified into different types:

Dry-process kilns:

- In-line kiln

- Waste heat boiler kiln (exhaust gas temperature: 600–900°C)

- Suspension preheater kiln (including those with and without a precalciner)

- Lepol kiln (semi-dry process, feed material temperature around 700°C)

Wet-process kilns:

- Long kiln with internal chains

- Slurry evaporator kiln

- Spray dryer kiln

- Vacuum filter waste heat boiler kiln (semi-wet process)

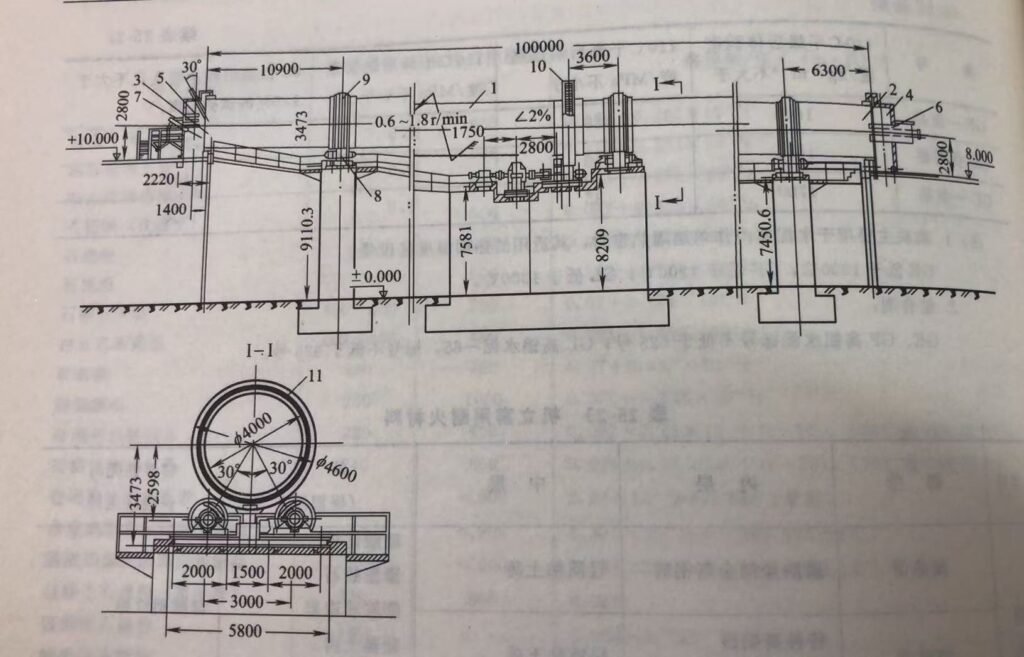

A rotary kiln is a long steel cylinder lined with refractory materials. It consists of the shell, kiln head with a burner, cooler, dust collector, and drive mechanism, as shown in Figures 25-6 and 25-7.

Rotary kilns have various applications beyond cement clinker production, including calcining bauxite, aluminum hydroxide, and carbon materials. Depending on production needs, kiln sizes vary—smaller kilns may have an internal diameter of about 1m and a length of around 20m, while larger ones range from 2.5–3.5m in diameter and 60–70m in length. Kilns used for bauxite calcination can reach 4m in diameter and 100m in length.

Based on operating temperature and process characteristics, the kiln is generally divided into three zones along its length: the preheating zone, the firing zone, and the cooling zone. To ensure material movement, the kiln is installed at an incline, typically 2.5%–5% of its total length.

Rotary kilns use pulverized coal, gas, or heavy oil as fuel. The heating temperature depends on process requirements, with cement clinker calcination reaching around 1500°C. In recent years, to conserve energy and utilize waste heat, precalciners and preheaters have been adopted. After discharge, clinker is cooled using grate coolers or single-drum coolers.

To ensure long-term operational efficiency and thermal resistance in rotary kilns, high-quality refractory linings are essential. Vuulcan specializes in manufacturing and supplying premium refractory bricks designed for extreme temperatures and harsh industrial environments, including cement, metallurgy, and chemical processing applications. Our products enhance kiln durability, reduce downtime, and optimize thermal performance.

25-6

25-7