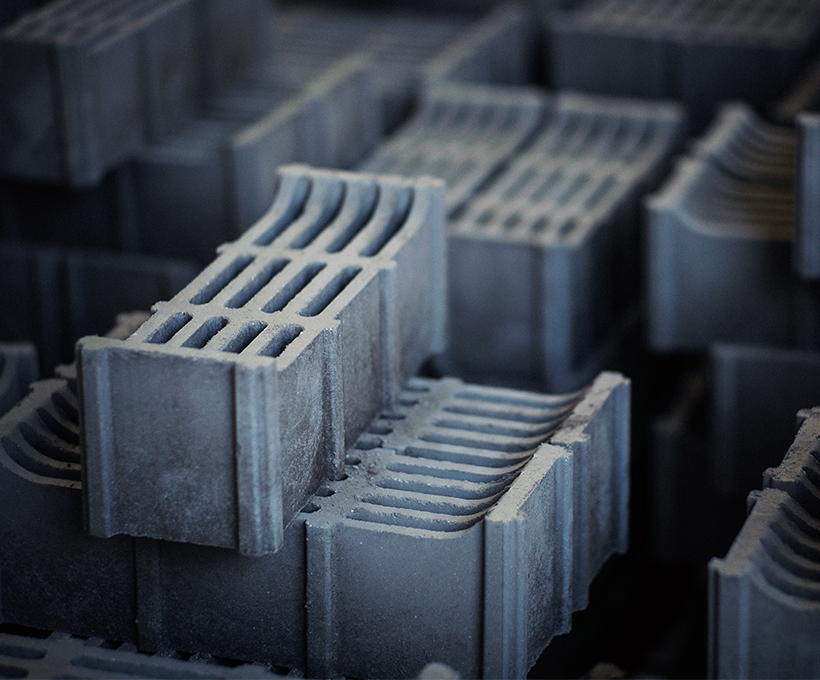

When it comes to high-temperature industrial applications, the right refractory materials make all the difference in performance, longevity, and safety. China Vuulcan’s Refractory Fireclay Bricks, also known as Alumina Silica Clay Fire Bricks, are specifically designed to handle the extreme conditions found in cupola furnaces, boilers, and other thermal processing systems. Their superior heat resistance, thermal stability, and mechanical strength make them a top choice for industries that demand reliable and durable furnace linings.

One of the standout features of these fireclay bricks is their high alumina and silica content, which ensures exceptional refractoriness, allowing them to withstand temperatures up to 1750°C (3182°F). This composition also provides low thermal conductivity, minimizing heat loss and improving overall energy efficiency. Additionally, their excellent thermal shock resistance makes them ideal for cupola furnaces, where rapid heating and cooling cycles are common, preventing cracks and structural damage over time.

Beyond heat resistance, these bricks offer outstanding mechanical strength, enabling them to endure abrasion, slag corrosion, and chemical erosion in harsh industrial environments. Available in both standard and custom sizes, they can be tailored to fit various furnace and boiler designs, ensuring optimal performance across different applications.

Key Features of Fireclay Bricks

- High Alumina & Silica Content

- Composed of high-purity alumina (Al₂O₃) and silica (SiO₂), these bricks provide excellent refractoriness, withstanding temperatures up to 1750°C (3182°F).

- The balanced composition ensures low thermal conductivity, reducing heat loss and improving energy efficiency.

- Superior Thermal Shock Resistance

- Designed to endure rapid temperature fluctuations without cracking, making them ideal for cupola furnaces where melting and cooling cycles are frequent.

- Excellent Mechanical Strength

- High compressive strength allows these bricks to resist abrasion, slag corrosion, and chemical erosion in boiler and furnace environments.

- Customizable Shapes & Sizes

- Available in standard and custom dimensions to fit various industrial furnace designs, ensuring optimal performance in different applications.

Applications in Industry

- Cupola Furnaces: Used for melting iron and other metals, requiring refractory materials that can endure extreme heat and molten metal exposure.

- Industrial Boilers: Protects boiler linings from high-pressure steam and combustion gases.

- Kilns & Incinerators: Suitable for cement, ceramic, and waste treatment industries.

Why Choose China Vuulcan Refractory Fireclay Bricks?

- Long service life, reducing maintenance and replacement costs.

- Cost-effective compared to other high-alumina refractories.

- Environmentally friendly, with low porosity and high density to minimize thermal waste.

These fireclay bricks are widely used in cupola furnaces for metal melting, industrial boilers, kilns, and incinerators, making them a versatile solution for industries like metallurgy, power generation, and waste treatment. Their long service life and cost-effectiveness make them a smart investment, reducing downtime and maintenance expenses while delivering consistent performance under extreme conditions.

For industries in need of a durable, high-temperature-resistant refractory solution, China Vuulcan’s Fireclay Bricks provide the reliability and efficiency required for demanding thermal processes. Whether for foundries, power plants, or manufacturing facilities, these bricks ensure optimal heat retention and structural integrity. If you’re looking for a refractory material that combines performance with longevity, these fireclay bricks are an excellent choice. Let us know how we can assist with your specific application needs!

- Preheating Insulation Material9 个产品

- Aluminum processing industry35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Bricks15 个产品

- Cement industry35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Environmental and energy solutions35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Industry Ceramic Material1 个产品

- Non-ferrous metal smelting industry35 个产品

- Preheating Insulation Material9 个产品

- Refractory Bricks15 个产品

- Refractory Raw Material11 个产品

- Refractory Raw Material11 个产品